Success Stories

Kurt Brinson of B&B Gear and Machine Co. describes how the Load & Go saves his shop time and money in the manufacturing process.

Mike Budde improved his production output by implementing the Load & Go VBX-160 in his shop

Mike Grossi rates the Load & Go RC a 5/5 in this in-depth machining review.

RAM Precision Industries was faced with the same challenges many other manufactures are today which is to do more with less. Learn how they overcame these challenges with Automation Within Reach.

Read More

As a new owner takes over a tooling shop, he must balance the company’s foundation with his goal of expanding the shop’s capacity to also take on production work.

Read More

Octane Workholding faced significant challenges that hindered their ability to meet customer demands and maintain competitive pricing. These challenges included bottlenecks, inefficiency, and a shortage of qualified labor for programming and machine tending.

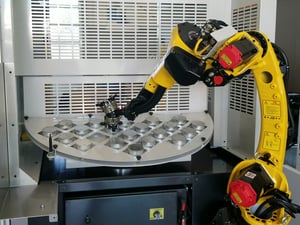

Read MoreHow Robotic Machine Tending Makes Automation Possible for any CNC Shop

This whitepaper delves into the several facets of machine tending that automation can improve as well as a few common misconceptions that would hinder one's consideration of robotic automation.