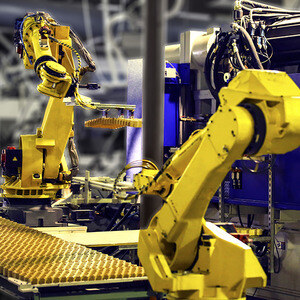

Flex Series RCX Automated Mill Tending Solution

Automate larger CNC payloads using the RCX Series mill tending solution from AWR. With three loading options, a max payload of 25 pounds, and capacity for up to 288 parts, operators can increase production efficiency without sacrificing quality.

Transform Your Manufacturing Process with Automated Mill Tending Solutions

Manual mill tending operations are a thing of the past with innovative automated capabilities from the RCX. With the addition of the RCX Series mill tending solution to your manufacturing lineup, you’ll see a greater return on your investment in no time.

Increase your CNC machine utilization by loading several different kinds of parts and machining all sides without reprogramming the automation.

With the RCX, your mill tending processes can run 24/7. You’ll see the results of a 2nd and 3rd shift without expanding your team of operators.

Increased part capacity and automated mill tending capabilities means more finished products in less time. And, increased productivity doesn’t come with additional overhead costs.

RCX with MultiGrip™

- Maximum Part Height: 9 in

- Maximum Part Depth: 8 in

- Maximum Part Width: 8.5 in

- Maximum Part Weight: 25 lbs

RCX Comes Standard with:

(1) Vise compatible with MultiGrip™

(1) MultiGrip™ base jaw

(1) 1.0" Top jaw

RCX with Pallet

COMING SOON!

Automation Within Reach will soon be offering the RCX pallet machine tending solution. Contact an automation expert today to learn more.

Effectively Handle Complex Parts

No need for gripper changes with MultiGrip™ jaws designed to quickly load and unload parts of all shapes and sizes, mimicking a hand-loaded process. This revolutionary automation technology transfers and turns parts by gripping the workholding rather than the product, ensuring any type of part can be milled from any side or angle for high-mix, low-volume manufacturing applications.

1.0" Top jaws:

$129 each

(7 additional max):

$499 each

See the RCX Series in Action

AWR RCX Series Specifications

Part Weight = Part+Jaws

Shelf Capacity: The cutoff point for a short vs tall part is 5.8" (Part+Jaws)

Explore AWR Solutions

The Plus Series offers flexible, pre-engineered machine tending solutions for fast implementation and high efficiency. These solutions can be configured for one or two machines and are compatible with both lathes and mills. The Plus Series ensures a quicker path to automation while still allowing for custom end-of-arm tooling to fit specific applications.

Explore the Plus Series

For unique production challenges, our Custom Integration solutions provide fully tailored automation designed to fit your specific manufacturing needs. From multi-step processes to highly specialized applications, our expert team engineers build and test complete systems that optimize efficiency, reduce labor, and improve consistency—bringing smarter automation within reach.

Explore Custom Solutions