Flex Series DC Machine Tending Solutions Increase Bandwidth for Your Team

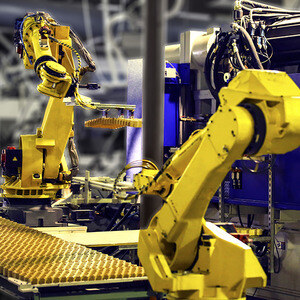

AWR’s DC automated machine tending solution uses robotic systems to load and unload parts from your CNC machine tool. For job shops that often deal with high-mix, low-volume production, our robotic automation technology allows you to maintain machine flexibility while producing high-quality finished parts up to 32 lbs.

How DC Series Machine Tending Solutions Maximize Efficiency

DC-1

- Maximum Part Weight: 9 lbs

DC-2

- Maximum Part Weight: 18 lbs

DC-3

- Maximum Part Weight: 32 lbs

Get The Most Out of Your CNC Lathe With Drawer Templates

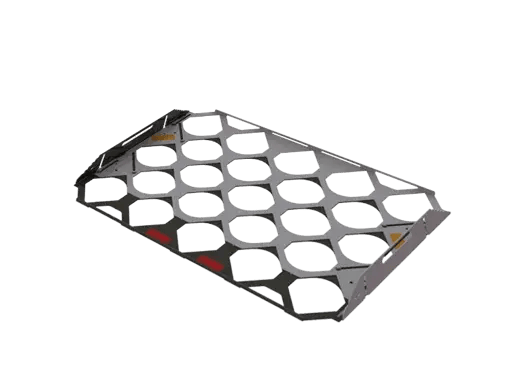

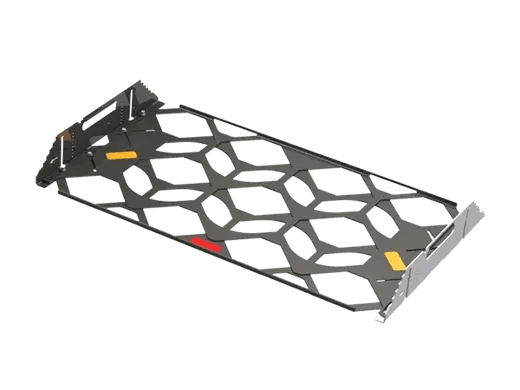

The AWR DC leverages a space-saving four-drawer system that maximizes part storage while minimizing floor space. Each drawer is equipped with an ergonomic, tool-less adjustable template that reliably positions a variety of part diameters and geometries. The robot loads & unloads one drawer at a time, allowing the operator to tend to the other three for uninterrupted operation.

Medium Template comes standard on any DC series unit.

Small | Optional Purchase

- Max Part Width: 3.0 in

- Part Capacity: 180 parts

Medium | Included

- Max Part Width: 5.0 in

- Part Capacity: 92 parts

Large | Optional Purchase

- Max Part Width: 8.0 in

- Part Capacity: 44 parts

Whether you're running slugs or tubes, large or small diameters, OD or ID gripping schemes, or tall or short parts, the gripper system is flexible enough to handle everything. A single-tool, quick-change system ensures fast and efficient changeovers.

Never programmed a robot before? No problem! The conversational touchscreen HMI, makes new part programming, robot recovery, and calling up existing programs a breeze. Just tap to answer a few process-related questions, and you're up and running.

AWR prioritizes safety without sacrificing accessibility. A combination of physical guarding and an area scanner with multiple safety zones protects operators while allowing them to access the machine tool control. The result is a safe yet unencumbered experience.

Give Operators an Extra Hand with Robotic Automation

Still, relying on manual lathe tending for your CNCs? Repetitive loading of raw materials and unloading of finished parts is not only time consuming, but can also be demanding of your team. The simple solution is robotic automation for your CNC lathes.

Continuous automation allows your CNC lathes to run uninterrupted around the clock, increasing efficiency and throughput. This frees operators from repetitive machine tending tasks, enabling them to focus on more complex and skilled activities that add greater value to the production process.

AWR’s machine tending robots execute tasks with high accuracy, reducing variability and human error. This results in uniformly produced parts which meet strict quality standards, crucial for many industries. Save time and effort by minimizing defects and the need for rework.

This seamless integration of robotic automation allows your CNC lathe to operate continuously with minimal downtime, significantly increasing its utilization. And, multiple drawer templates allow for parts of different sizes to be loaded at once, saving time alternating between jobs.

Robotic automation allows you to leave the repetitive and time consuming tasks to the robots. Using the icon-based touchscreen display, your operators can adjust programming functionality as needed, without the need for in-depth technical training.

See the DC Series Machine Tending Solution in Action

DC Series Specifications

Explore AWR Solutions

The Plus Series offers flexible, pre-engineered machine tending solutions for fast implementation and high efficiency. These solutions can be configured for one or two machines and are compatible with lathes and mills. The Plus Series ensures a quicker path to automation, allowing custom end-of-arm tooling to fit specific applications.

Explore the Plus Series

For unique production challenges, our Custom Integration solutions provide fully tailored automation designed to fit your specific manufacturing needs. From multi-step processes to highly specialized applications, our expert team engineers build and test complete systems that optimize efficiency, reduce labor, and improve consistency—bringing smarter automation within reach.

Explore Custom SolutionsGet Started with DC Series Machine Tending Automation!

With labor growing even more difficult to find, keep, and train, avoid these hardships and increase uptime by adding unmanned machining to your operation. Our automated machine-tending solutions maximize efficiency and the flexibility you need to keep competitive in an ever-growing industry.