Custom Automation Solutions

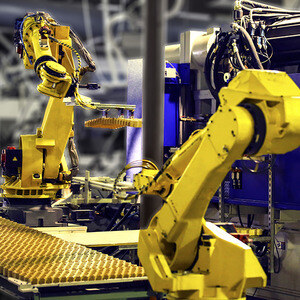

Custom Automation, Tailored to Your Production

Automation Within Reach specializes in robotic solutions that optimize workpiece flow, enhance throughput, reduce direct labor costs, and ensure consistent part quality with faster deliveries. With over 1,000 successful installations across U.S. factories and 90+ years of expertise in the machine tool industry, AWR has the knowledge and experience to develop a custom automation solution tailored to your needs.

Smart, Efficient Automation for Every Stage of Production

Automation Within Reach eliminates unnecessary manual touches throughout your component manufacturing process. Our team designs, builds, and tests each system to ensure it meets your needs and delivers the expected efficiency. With custom automation, more integration often means better results. By automating as many steps as possible, we reduce tedious labor, maximize robot and machine utilization, minimize scrap, and lower the per-part cost of production.

As a full-service machine tool automation integrator, we take a holistic approach—optimizing your entire manufacturing process for maximum efficiency and performance.

Raw Material Handling

Our custom fixtures ensure that parts are organized for seamless automated pick-up, reducing manual handling and improving efficiency.Machine Load & Unload

From loading raw materials to unloading finished parts, our automation moves products seamlessly through each step—whether it’s additional machining, inspection, assembly, or packaging.2D Vision

Our 2D vision technology allows operators to place parts on a conveyor without worrying about orientation. The robot identifies, selects, and correctly positions each part for machine loading.Material Removal

Our robotic solutions enhance precision in trimming and deburring, optimize flexibility and accuracy, reduce skilled labor reliance, and improve part consistency through automation.3D Vision

Our advanced 3D vision bin-picking technology eliminates the need for special packaging or staging. Robots can pick raw materials directly from crates, minimizing manual labor and streamlining production.In-Process Inspection

We integrate inspection directly into the process, using real-time data to adjust machining parameters automatically. This ensures precision, reduces human error, and minimizes scrap.Automated Assembly

From installing bearings to assembling bolted joints, our solutions remove manual labor and errors, ensuring consistent, high-quality assembly.

Part Cleaning

We automate part handling for cleaning systems, ovens, and rust inhibitor stations, enhancing efficiency and consistency in your finishing processes.Palletizing & Packaging

Our solutions enable flexible unloading of finished parts—whether into racks, standard or custom pallets, or boxes—ensuring smooth transitions to the next stage of your operation.

Proven Automation Expertise, Backed by Results

With a track record of success in manufacturing automation, AWR delivers solutions that drive efficiency, consistency, and productivity. Partner with a team that understands automation—because precision and reliability matter.See the Possibilities!

Take a look at some of the custom automation magic we've created! See how we have implemented cutting-edge integrated systems that drive efficiency and productivity.

-1.webp?width=300&name=AWR_CUSTOM_WATTS_THUMBNAIL_2025_(MKT)-1.webp)

.webp?width=300&name=AWR_CUSTOM_ALLISON_THUMBNAIL_2025_(MKT).webp)

Explore AWR Flex & Plus Series

The AWR Flex Series offers standard automation solutions designed to boost productivity and reduce costs. Our DC, RC, and RCX systems provide reliable automation for single machines or workflows, optimizing machinist utilization and profit margins. These solutions minimize downtime, streamline machine loading and unloading, and offer straightforward implementation for immediate productivity gains.

Explore the Flex Series

The Plus Series elevates automation with pre-engineered machine tending solutions designed for quick implementation and high efficiency. With flexible configurations for single or dual-machine operation and custom end-of-arm tooling, the Plus Series ensures seamless integration, delivering reliable performance tailored to your production needs.

Explore the Plus Series