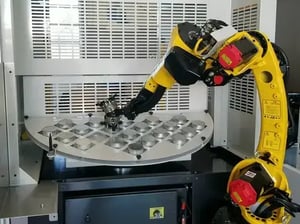

Flex Series: Easy-to-Use RC Series Rotary CNC Machine Tending

AWR's machine tending robots provide comprehensive automation solutions for CNC lathe operations, ensuring optimal efficiency and precision. The AWR RC maximizes productivity while maintaining the highest quality standards, featuring unmatched performance and reliability.

Benefits of the RC Series

Compact CNC Machine Automation

With a small footprint, the RC Series can be easily added to CNC lathes, no matter the size of your factory or shop floor.

Flexible for Different Part Sizes

RC-1

- Maximum Part Weight: 9 lbs

RC-2

- Maximum Part Weight: 18 lbs

RC-3

- Maximum Part Weight: 32 lbs

Get The Most Out of Your CNC Lathe With Part Templates

With templates, you can load raw materials of different shapes and sizes, eliminating manual processes that slow production. Just insert the materials and let the automation tackle the rest!

X-Small

- Max Part Diameter: 2 in

- Part Capacity: 166 parts

Small

- Max Part Diameter: 3 in

- Part Capacity: 76 parts

Medium

- Max Part Diameter: 4 in

- Part Capacity: 42 parts

Large

- Max Part Diameter: 5 in

- Part Capacity: 28 parts

Flexible Gripper Design

Whether you're running slugs or tubes, large or small diameters, OD or ID gripping schemes, tall or short parts, the AWR RC gripper system is flexible enough to handle it all. When an adjustment is required, a single-tool, quick-change system ensures fast and efficient changeovers.

See the AWR RC in Action

Never programmed a robot before? No problem! The conversational touchscreen HMI, makes new part programming, robot recovery, and calling up existing programs a breeze. Just tap to answer a few process-related questions, and you're up and running.

The AWR RC prioritizes safety without sacrificing accessibility. A combination of physical guarding and an area scanner with multiple safety zones protects operators while allowing them to access the machine tool control. The result is a safe yet unencumbered experience.

The AWR Flex Series RC and DC are designed with user-friendliness, making them exceptionally easy to operate. This ease of use, advanced software, and safety combination make the AWR Flex Series an ideal choice for a wide range of manufacturing environments.

Transform Your Job Shop with Robotic Automation

Loading and unloading parts using traditional manual processes can be time consuming and repetitive, but with the RC automation series, your operations are streamlined.

The addition of robotic automation to your CNC lathes means continuous machine tending around the clock, giving you the performance of 2nd and 3rd shifts without additional labor or additional CNC machines.

Robotic automation means machinists don’t need to be present to repeatedly load and unload parts. With the RC Series, operators can focus on high-value tasks while the automation addresses repetitive and time-consuming lathe tending operations.

Thanks to increased throughput and 24/7 operations, you’ll be able to load raw materials and unload finished parts quickly, so you can deliver high quality parts to customers.

Even the smallest variations in manual lathe tending can lead to inconsistent finished parts. Automated lathe tending ensures all parts are loaded accurately and consistently for high-quality results, even with tight tolerances, resulting in minimal waste.

RC Series Specifications

Ready to Get Started With Automation?

With labor growing even more difficult to find, keep, and train, avoid these hardships and increase uptime by adding unmanned machining to your operation. Our automated machine-tending solutions maximize efficiency and the flexibility you need to keep competitive in an ever-growing industry.