Maximize Productivity with CNC Automation

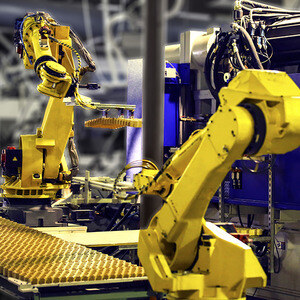

One Brand Infinite CNC Automation Possibilities

Automation Within Reach Unveils Comprehensive Solutions for Manufacturers

Automation Within Reach (AWR) has evolved into a comprehensive automation solutions provider. This expansion unites our standard and custom automation solutions under a single, dynamic brand, delivering a full range of machine-tending solutions for manufacturers at every stage of their automation journey.

How CNC Automation Can Unleash Efficiency for Manufacturers

Automation Within Reach (AWR) delivers accessible and efficient CNC machine tending automation solutions to manufacturers. Proudly made in America, our standard solutions, pre-engineered cells, and custom automation integrations empower businesses to optimize workflows, reduce labor costs, and achieve consistent part quality. With a commitment to innovation and customer success, AWR makes automation accessible to manufacturers.

Discover our CNC Automation Solutions.

In today’s competitive manufacturing landscape, maximizing productivity and maintaining top-tier quality is essential. The AWR Flex Series provides comprehensive automation solutions designed specifically for CNC lathe and mill operations. Our systems address the challenges of manual processes, offering seamless integration, increased throughput, and consistent part quality.

Explore Standard Automation

Boost efficiency and minimize downtime with Automation Within Reach's pre-engineered CNC machine-tending solutions designed for rapid implementation and maximum productivity. The Plus Series offers single—or dual-machine operation, custom end-of-arm tooling (EOAT), and three-cell options, Drawer, Conveyor, and Pallet, to fit your unique needs.

Explore Pre-Engineered Automation

Our strength lies in eliminating all customer part touches in a component manufacturing process. We design, build, and test your system to ensure your project meets your expectations.

Custom automation integration removes more tedious labor, increases robot and machine utilization, reduces scrap, and lowers the per-part price of the manufactured component.

Optimize Your Production with Automated Lathe & Mill Tending

Take your machining operations to the next level with advanced automation solutions for both lathe and mill tending. Our robotic systems are designed to streamline production, enhance precision, and reduce labor costs—allowing your workforce to focus on higher-value tasks.

Key Benefits:

Increased Efficiency: Automated material handling and machine tending minimize downtime and optimize throughput.

Improved Accuracy: Consistent part quality with reduced errors compared to manual operations.

Enhanced Safety: Robots take on hazardous tasks, creating a safer work environment.

Reduced Labor Costs: Free up skilled workers for more complex and strategic activities.

Seamless Integration: Easily integrate with existing lathe and milling setups for a smooth transition to automation.

Discover how automation can transform your shop floor and keep you ahead of the competition.

Discover how lathe tending robots can revolutionize your manufacturing operations.

Automation Success Stories: Real Results, Real Impact

See how manufacturers like you have transformed their operations with Automation Within Reach. From increasing productivity to reducing labor challenges, our machine tending solutions deliver measurable results. Explore our success stories and discover what’s possible for your shop.

Gilco Manufacturing Inc. increased production and reduced downtime with an AWR CNC mill tending solution.

Kurt Brinson of B&B Gear and Machine Co. describes how AWR saves his shop time and money in manufacturing.

Mike Budde improved his production output by implementing AWR CNC mill tending solutions in his shop.

Upcoming Events & Live Demos

Join Automation Within Reach at industry events, trade shows, and live demos to see our CNC automation solutions in action. Meet our experts, explore hands-on demonstrations, and discover how our machine tending systems can elevate your production. Check out our upcoming events and plan your visit!